Technologies & Licensing

From Burden to BenefitOur patented technologies work together to turn biosolids from a problem into a useful product.

The Growing Biosolids Challenge

Every day, wastewater treatment plants across America face the challenge of managing tons of biosolids. Without proper dewatering systems in place, municipalities are faced with higher transportation costs to haul away the heavier, wet material.

Landfills are reaching capacity, and facilities are struggling with growing volumes and increasing regulations. Alternatives like incineration are costly and harmful to the environment.

As challenges grow, communities need safer, more sustainable, and efficient long-term solutions.

That’s where Merrell Bros. steps in.

In our 40+ years in the biosolids management industry, Merrell Bros. has worked with nearly every Class A and Class B treatment technology on the market.

That experience has given us a unique perspective on what works, what doesn’t, and where municipalities need better solutions.

This is why we set out on a mission to create forward-thinking technologies that reduce costs, ease operational burdens, and provide real, sustainable alternatives to traditional disposal methods.

Our Patented Technologies

Merrell Bros., Inc. currently holds 7 U.S. patents for biosolids processing technologies, with 6 additional patents pending. Our licensing partners receive full support, from permitting assistance and training to long-term maintenance and service. We don’t just provide technology, we provide peace of mind.

Solar-Thermal Pasteurization uses enclosed greenhouse drying and a specialized oven system to dry out biosolids, significantly reducing transportation costs while creating a safe, Class A fertilizer product.

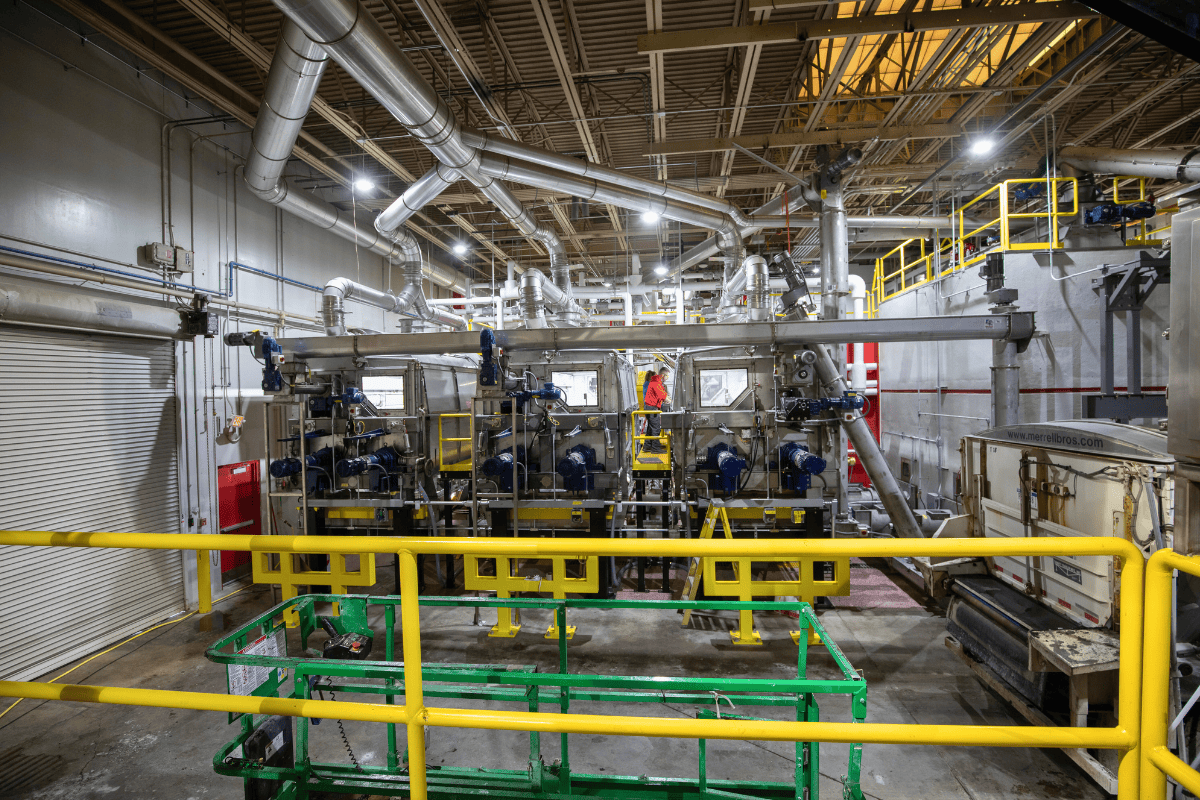

Double Drum Drying uses steam-heated rotating drums and a specialized oven system to dry out biosolids, significantly reducing transportation costs while creating a safe, Class A fertilizer product.

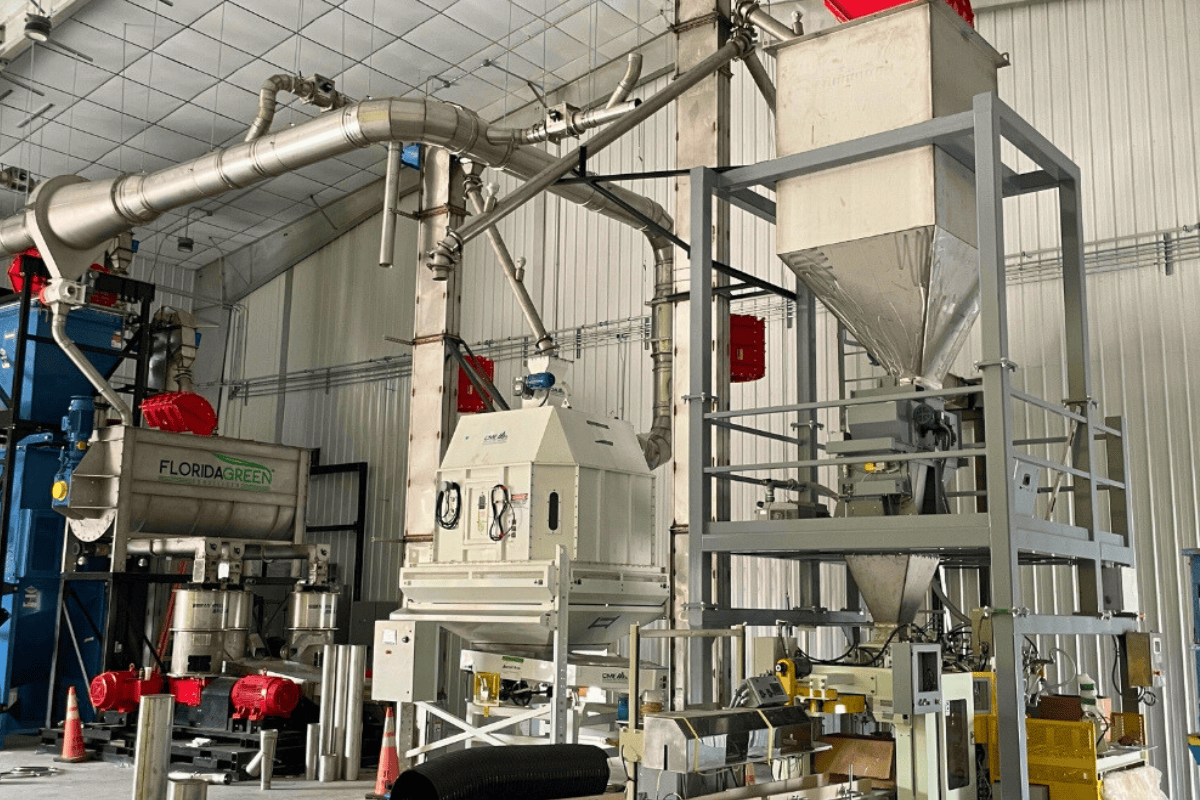

Pelletization takes dried and treated biosolids and transforms them into clean, uniform fertilizer pellets. Our fully automated pelletization system seamlessly integrates with our Solar-Thermal or Double Drum technologies. It also connects easily to any wastewater treatment plant with dewatering capabilities.

These services (or systems/processes/technologies) incorporate proprietary technologies protected by one or more patents or pending patent applications. View our Patents.

Ask us about Public-Private Partnerships

Many Merrell Bros. projects are delivered through Public–Private Partnerships, combining the strengths of municipal ownership with private-sector innovation and operational expertise. This approach allows cities, counties, and utilities to implement advanced biosolids treatment and reuse technologies without bearing the full financial or technical burden upfront.

Through these partnerships, Merrell Bros. provides the design, construction, operation, and maintenance of the biosolids processing systems, while the public partner retains oversight and long-term benefit. This structure ensures accountability, performance guarantees, and measurable results that protect both ratepayers and the environment.

The result is a shared investment model that delivers long-term savings, regulatory compliance, and community value — turning a traditional waste challenge into a sustainable public asset.

Benefits for Municipalities & Wastewater Treatment Facilities

✅ Lower hauling and disposal costs

✅ Meet Class A standards

✅ Less landfill waste

✅ Environmentally friendly

✅ Long-term sustainability

✅ Higher cost-savings over time

✅ Beneficial Re-use

✅ Fertilizer pellets allow for easier handling and less dust pollution

✅ Produces a marketable nutrient-rich fertilizer product

✅ Backed by patented, proven systems

✅ Better odor control

✅ Meets increasingly strict and ever-changing regulatory standards

✅ More predictable numbers and better forecasting

✅ Increased operational efficiency

✅ Merrell Bros. does all the heavy-lifting

✅ Avoid costly emergency cleanouts & less frequent lagoon cleanouts needed

Proven, Field-Tested results

Today, those innovations are helping utilities across the country turn a growing challenge into a reliable, sustainable opportunity. See some of our case studies to learn more about how MB Technologies are helping municipalities acrossed the United States.

Pasco County partnered with Merrell Bros. to implement our Solar-Thermal Pasteurization technology, transforming biosolids management…

Kokomo, IN partnered with Merrell Bros. to deploy our Double-Drum Drying technology system to deliver a long-term, sustainable solution to…

The City of Kennewick, WA partnered with Merrell Bros. to modernize its biosolids operation with our Solar-Thermal Pasteurization and…

Are you ready to be at the forefront of sustainable biosolids management?

We’re confident that our technologies can improve your operation and reduce the headaches you face each day. Our team is always here to answer questions and help you determine if our technology is the right fit for your operation.

FAQs

How difficult is it to integrate with our current dewatering or drying setup?

Integration is straightforward. Our technologies are modular and can connect directly to existing dewatering equipment such as centrifuges or belt presses. The design process includes a full compatibility review to ensure seamless integration with minimal disruption to current operations.

Can Merrell Bros. technologies save my operation money?

While these technologies require an upfront investment to get up and running, they are designed to pay off significantly over time. Merrell Bros. systems improve operational efficiency, reduce costly maintenance and emergency cleanouts, and help facilities plan more accurately with predictable performance and lower downtime. By drying and stabilizing biosolids on-site, transportation costs drop dramatically — fewer loads, lighter material, and less fuel. In many cases, facilities can also generate revenue through fertilizer sales.

How does the system control odor levels during and after processing?

Odor control is a key design feature in every Merrell Bros. technology. Our Solar-Thermal Pasteurization and Double Drum Drying systems are fully enclosed to minimize odor release and include integrated biofiltration systems that capture and neutralize air from processing areas. Controlled airflow and temperature management prevent odor-causing gases from forming, while enclosed conveyors and covered storage bunkers contain material after treatment.

Once the biosolids are fully dried and pelletized, odors are virtually eliminated. The finished fertilizer pellets are clean, dry, and stable — making them safe to store, transport, and use without producing unpleasant smells.

Does Merrell Bros. help with permitting and compliance documentation?

Yes. Our team assists with the data, testing, and documentation needed for permitting, compliance verification, and Class A certification.

Can Merrell Bros. technologies connect to existing wastewater treatment plant systems?

Absolutely. Our systems can be added to facilities with existing dewatering capabilities. They are flexible and modular, allowing easy integration into your current operations without major redesigns.

What are Class A biosolids, and why do they matter?

Class A biosolids meet the highest EPA standards for pathogen and vector reduction, making them safe for use in agriculture, landscaping, and public applications. This classification allows biosolids to be reused safely instead of being sent to landfills or incinerators.

Can these technologies work together?

Yes. Each system is designed to integrate seamlessly. The Solar-Thermal or Double Drum technologies handle the drying and sanitizing, and the Pelletization system finishes the process by forming the final pellet product. Together, they create a full, end-to-end biosolids management solution.

What problem do Merrell Bros. technologies solve?

Merrell Bros. technologies help municipalities and industries safely manage and reuse biosolids — the byproduct of wastewater treatment. Our systems turn biosolids from a costly disposal problem into a marketable, Class A fertilizer that benefits farmers, communities, home owners, golf courses, businesses, and the environment.

How do these technologies benefit communities and municipalities?

Our systems lower hauling and disposal costs, reduce landfill use, and help meet regulatory standards. By turning biosolids into Class A fertilizer, communities can reduce waste, support local agriculture, and create new opportunities for resource recovery.

How much space do these systems require to install at an existing wastewater treatment plant?

System size depends on plant capacity and the technology selected. The Solar-Thermal Pasteurization setup uses greenhouse structures and typically requires more footprint but minimal utility demand, while Double Drum Drying offers a more compact, mechanical option ideal for space-limited sites. Our engineering team custom-designs each system to fit available space and operational needs.

Can the technology run continuously, or does it require batch processing?

Both systems can operate continuously. The Double Drum Dryer runs as a continuous feed system, while the Solar-Thermal Pasteurization process uses a daily batch cycle that’s automated for consistency. Each system is designed for steady throughput and minimal operator input.

What level of operator training is needed to run and maintain the system?

Merrell Bros. provides full training during installation and startup. Operators learn how to monitor system performance, perform light maintenance, and manage data reporting. The systems are built for simplicity, using automation and controls that make daily operation easy and reliable.

Can the system handle variable feed rates or changes in biosolid composition?

Yes. Both technologies are built to handle fluctuations in feed rate and material consistency. Automated controls adjust temperature, speed, and retention time to maintain uniform drying and pasteurization even when conditions change.

What’s the typical installation timeline for a new system?

Installation timelines vary depending on project size and permitting requirements, but most systems can be fully operational within 6–18 months of design approval. Our team works closely with each client to streamline the process from start to finish.

Are these systems scalable for different plant sizes and capacities?

Absolutely. Each technology is modular and can be scaled to match a small municipal facility or a large regional treatment plant. Systems can also be expanded later as capacity needs grow.

What kind of automation and monitoring controls are included?

All Merrell Bros. systems feature PLC-based automation and real-time monitoring. Operators can track temperatures, feed rates, and output quality through intuitive dashboards, ensuring performance and compliance with Class A biosolids standards.

What are the routine maintenance requirements?

Routine maintenance is minimal compared to traditional dryers or incinerators. Tasks typically include visual inspections, cleaning air filters, lubricating moving parts, and verifying sensor calibration. Our team will provide maintenance, training, and ongoing support as needed.

How does the system handle unplanned shutdowns or equipment failures?

Each system includes safety and bypass protocols to prevent damage or downtime. Redundant components and automatic shutdown sequences protect the equipment, and Merrell Bros. offers rapid-response service and spare parts support.

How does this technology reduce maintenance costs compared to traditional methods?

By removing moisture efficiently and maintaining steady temperatures, our systems reduce corrosion, clogging, and mechanical strain. This lowers unplanned maintenance and extends the life of your equipment.

How does your technology meet EPA and state biosolids standards for Class A certification?

Both the Solar-Thermal Pasteurization and Double Drum Drying systems meet or exceed EPA 40 CFR Part 503 requirements for Class A pathogen and vector attraction reduction. Continuous temperature monitoring and documentation ensure compliance.

What are the emissions or odor levels compared to incineration or landfill disposal?

Our processes produce significantly lower emissions than incineration and minimize odor through enclosed systems and biofiltration. This helps facilities maintain regulatory compliance and better community relations.

How does the process support sustainability and carbon reduction goals?

By reusing biosolids instead of landfilling or incinerating them, facilities lower greenhouse gas emissions, conserve landfill space, and recycle valuable nutrients back into the soil — creating a measurable environmental benefit.

What kind of fertilizer is produced, and can it be customized?

The Pelletization system produces uniform, dust-free fertilizer pellets. Nutrient content can be tailored with additives or blended to meet a variety of needs.

Can the fertilizer be stored long-term without losing quality or safety?

Yes. Once dried and pelletized, the fertilizer is shelf-stable and can be safely stored for extended periods in covered facilities with minimal risk of odor or degradation.

Can your systems process materials other than biosolids, such as food waste or digestate?

In many cases, yes. Our technologies can handle similar organic materials, including anaerobic digestate, food waste slurry, and agricultural byproducts. Our engineers evaluate each material for compatibility.

Does Merrell Bros. provide system monitoring or performance analytics?

Yes. We offer performance tracking and data analytics through integrated control systems. Clients can monitor throughput, energy use, and drying efficiency to optimize performance and costs.

What kind of training and support do operators receive after installation?

Merrell Bros. provides comprehensive operator training, including on-site instruction, maintenance workshops, and refresher courses. Our support team is always available for troubleshooting and ongoing education.

Do you offer pilot testing or demonstrations before full-scale implementation?

Yes. Pilot testing is available for clients who want to validate performance before committing to full-scale deployment. Demonstrations can also be arranged at active facilities using Merrell Bros. technology.

What makes your team uniquely qualified to support municipal and industrial clients?

Our experience spans operations, engineering, fabrication, transportation, and environmental services, giving us a 360° understanding of the biosolids industry. We don’t just design systems — we operate them every day.